HARD MILLING & HIGH-SPEED MACHINING

The hard milling and high-speed machining (HSM) process have become crucial in today's competitive environment.

Achieving hard milling is more than just being equipped with stable and rigid high-speed machining (HSM) centers possessing unique capabilities strictly for ultra-high precision milling to exacting sizes and polish-free finishes.

The other components that make us here at SURKUT Machine successful in the hard milling process include:

- SOFTWARE - CAM-TOOL software, an elite CAD/CAM system specifically designed for hard milling applications

- TOOLING - heat shrunk and balanced tool holders that are capable of cutting at 24,000 RPM from high-end suppliers

- PEOPLE - experienced personnel with a thorough understanding of all of these principles

- EQUIPMENT - state-of-the-art CNC equipment with high-quality features and large XYZ travels

Areas of Expertise

|

|

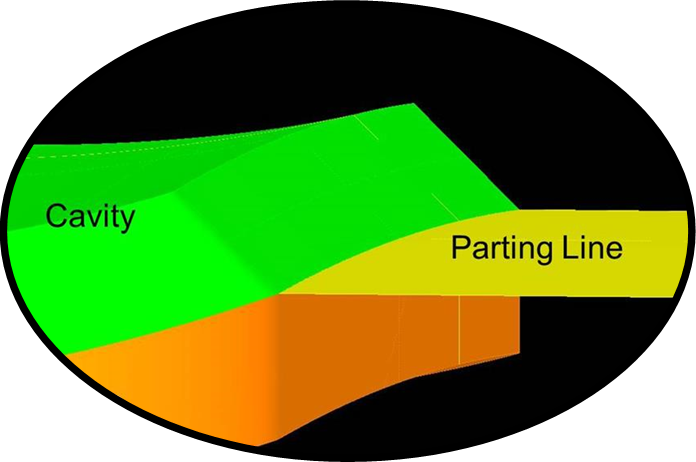

Negative Stock MachiningWhat exactly is Negative Stock Machining?It is the process of creating a small gap between the parting line and shut-off surfaces. Benefits of Machining to Negative Stock

It is also essential for multi-cavity and colour molds. Learn more about this technique here. |

High-Speed Rib Cutting Has Its AdvantagesWe have the techniques and cutting tools to effectively cut ribs rather than using EDM processes that are both costly and time consuming. Advantages: fewer processes = fewer errors shorter lead times lower cost versus traditional methods Disadvantages:depth restrictions a sharp corner |

|

Our Portfolio

|

|

|

World-Class Machine Tools from: |

||

|

|

||

|

|

|