INSPECTION & QUALITY CONTROL

SURKUT Machine uses the latest inspection equipment to ensure the best surface finish and accuracy.

SURKUT Machine uses the latest inspection equipment to ensure the best surface finish and accuracy.

We have earned the reputation for being an industry leader who provides exceptional quality which is evident since our inception and continues to be at the forefront of our commitment to our customers.

Our entire team is committed to continuous improvement in order to achieve the highest quality possible through the investment in the latest innovations and taking special pride in the quality of the machined components we produce.

At the end of the day, a quality part that is extremely accurate and well within the tolerances as set forth by the customer is what sets us apart from the competition.

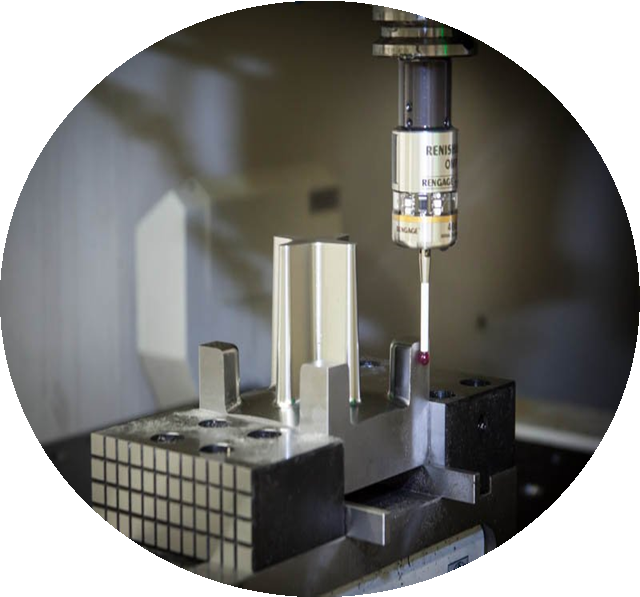

OMV Technology

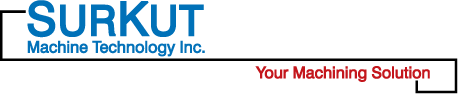

With our Yasda CNC Jig Borer equipped with a Renishaw OMP400 along with CappsNC programming software we are able to measure your part in-process and when it's complete to give you assurance that it is correct and within exacting tolerances.

Benefits of OMV

- Reduced Setup Time and Costs

- Allows Operator to Verify Setup

- Verify Critical Part Features

- Reduced Verification Cycle Times

- Eliminate Secondary Verification Operations

- Minimize Tooling Offset Errors

- Eliminate Need for Rework

A detailed report is also generated and provided to the customer upon request to confirm critical part features are well within the specified tolerances you require.

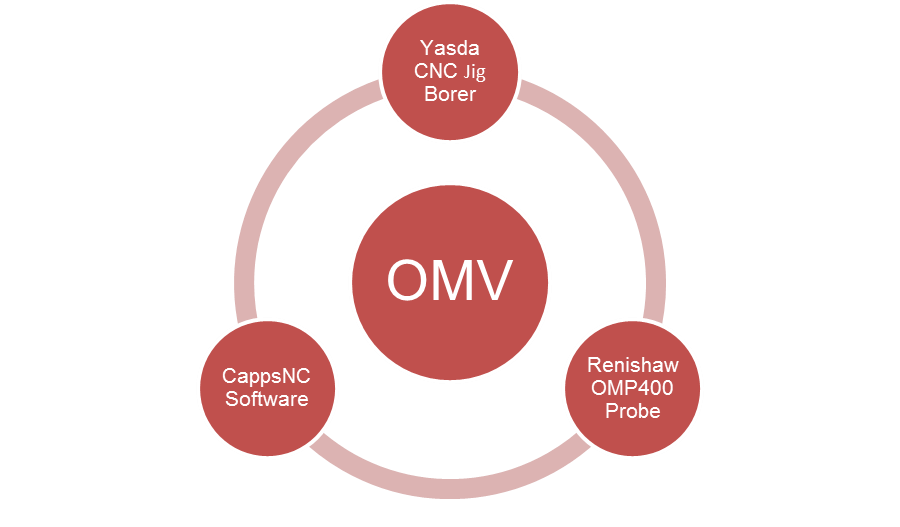

3D Scanning

Using a state-of-the-art portable metrology arm from Hexagon Manufacturing Intelligence, we are able to fully scan your part.

The 2.0M, 7-axis ROMER Absolute portable arm is an all-purpose metrology tool, with an integrated RS4 laser scanner. It allows us to offer accurate high-speed scanning for a multitude of parts and applications throughout the entire manufacturing process.

PolyWorks Inspector, which is a powerful software solution that uses high-density point clouds to control the quality of castings, die and more.

In-Process Inspection

In addition to the technology listed above, we perform manual inspections during all machining operations and between multiple setups to assure you of the quality you expect from us here at SURKUT Machine Technology Inc.

Utilizing top-notch measuring equipment from Mitutoyo and other leading manufacturers allows us to measure and confirm part conformance where not otherwise achievable by other modern techniques.

Inspection Software

(1) CappsNC Programming Software License (with CappsNC Execution Module)

(1) PolyWorks Inspector Premium + Meshing Software License