EQUIPMENT

At SURKUT Machine, we pride ourselves in having the latest technology available to help our customers find solutions to their machining challenges.

Our state-of-the-art facility features the following capabilities:

CNC JIG BORERS

Yasda YBM-9150V CNC Jig Borer (w/ APC)

- MACHINE TRAVELS

- X: 1,500mm (59.1")

- Y: 900mm (35.4")

- Z: 450mm (17.7")

- SPECIFICATIONS

- Spindle: BT40 BIG-Plus | RPM: 24,000

- (2) 1500 x 900mm Pallets

- Load Capacity: 3,000 kg. (6,614 lbs.)

- ATC Capacity: 100 Tools

- Control: Fanuc 31i-MODEL B5

- TOOLING

- Equipped with Yasda YPV-125 Precision Vise

- Through-Spindle Coolant System

- BLUM Laser Tool Probe

- Renishaw OMP400 Part Probe

- Renishaw Tool Setter Touch Probe

- Bluebe MQL System

(2) Yasda YBM-9150V CNC Jig Borers

- MACHINE TRAVELS

- X: 1,500mm (59.1")

- Y: 900mm (35.4")

- Z: 450mm (17.7")

- SPECIFICATIONS

- Spindle: BT40 BIG-Plus | RPM: 24,000

- Load Capacity: 3,000 kg. (6,614 lbs.)

- ATC Capacity: 60 Tools

- Control: Fanuc 31i-MODEL B5

- TOOLING

- Through-Spindle Coolant System

- BLUM Laser Tool Probe

- Renishaw OMP400 Part Probe

- Renishaw Tool Setter Touch Probe

- Bluebe MQL System

Yasda YBM-9150V VII CNC Jig Borer

- MACHINE TRAVELS

- X: 1,500mm (59.1")

- Y: 900mm (35.4")

- Z: 450mm (17.7")

- SPECIFICATIONS

- Spindle: BT40 BIG-Plus | RPM: 24,000

- Load Capacity: 3,000 kg. (6,614 lbs.)

- ATC Capacity: 60 Tools

- Control: Fanuc 31i-MODEL B5 Plus+iHMI

- TOOLING

- Through-Spindle Coolant System

- BLUM Laser Tool Probe

- Renishaw OMP400 Part Probe

- Renishaw Tool Setter Touch Probe

- Bluebe MQL System

Yasda YBM-950V CNC Jig Borer

- MACHINE TRAVELS

- X: 900mm (35.4")

- Y: 500mm (19.7")

- Z: 350mm (13.8")

- SPECIFICATIONS

- Spindle: BT40 BIG-Plus | RPM: 24,000

- Load Capacity: 800 kg. (1,764 lbs.)

- ATC Capacity: 30 Tools

- Control: Fanuc 31i-MODEL B5

- TOOLING

- BLUM Laser Tool Probe

- Renishaw OMP400 Part Probe

- Renishaw Tool Setter Touch Probe

- Bluebe MQL System

VERTICAL MACHINING CENTERS

Johnford Hi-Net DMC-1600

- MACHINE TRAVELS

- X: 1,600mm (63.0")

- Y: 1,300mm (51.0")

- Z: 800mm (31.5")

- SPECIFICATIONS

- Spindle: HSK-63A | RPM: 24,000

- Load Capacity: 13,200 lbs.

- ATC Capacity: 40 Tools

- Control: Fanuc 18i-MB

- TOOLING

- BLUM Laser Tool Probe

- UNIST MQL System

Tongtai Topper MDV-812

- MACHINE TRAVELS

- X: 1,200mm (47.2")

- Y: 800mm (31.5")

- Z: 500mm (19.7")

- SPECIFICATIONS

- Spindle: HSK-63A | RPM: 24,000

- Load Capacity: 4,400 lbs.

- ATC Capacity: 16 Tools

- Control: Fanuc 18i-MB

- TOOLING

- Equipped with 4th Axis Rotary Table

- BLUM Laser Tool Probe

- UNIST MQL System

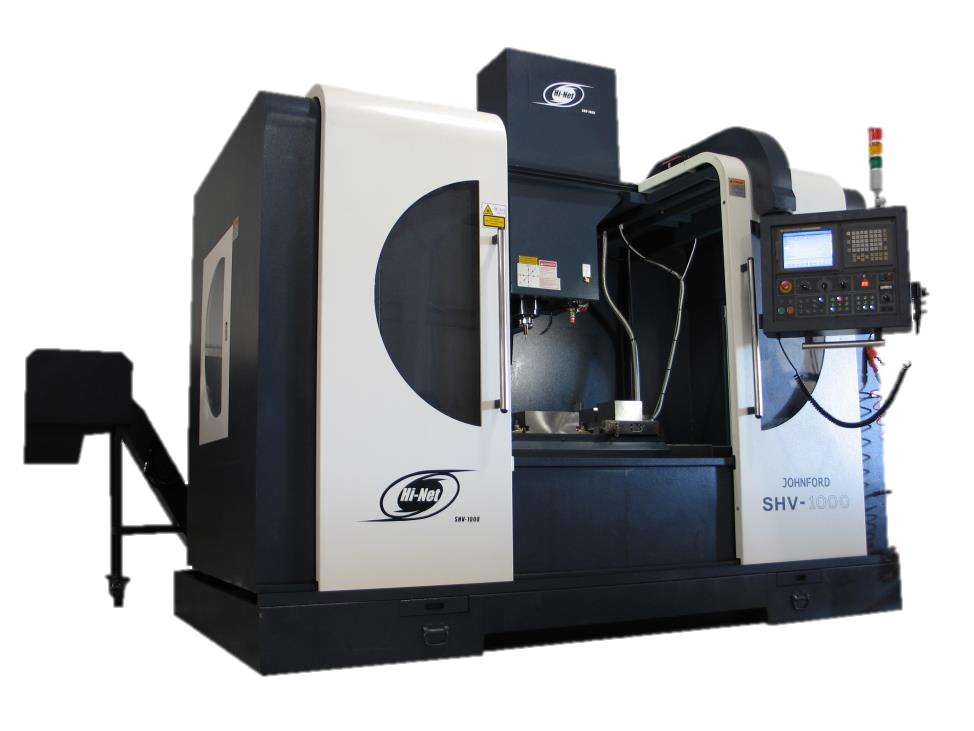

Johnford Hi-Net SHV-1000

- MACHINE TRAVELS

- X: 1,040mm (41.0")

- Y: 610mm (24.0")

- Z: 508mm (20.0")

- SPECIFICATIONS

- Spindle: HSK-63A | RPM: 24,000

- Load Capacity: 2,840 lbs.

- ATC Capacity: 24 Tools

- Control: Fanuc 18i-MB

- TOOLING

- BLUM Laser Tool Probe

- UNIST MQL System

5-AXIS VERTICAL MACHINING CENTER

Makino D500

- MACHINE TRAVELS

- X: 550mm (21.7")

- Y: 1,000mm (39.4")

- Z: 500mm (19.7")

- A: 150° (+30° to -120°)

- C: 360° (continuous rotation)

- SPECIFICATIONS

- Spindle: HSK-63A | RPM: 20,000

- Load Capacity: 350 kg. (771.62 lbs.)

- ATC Capacity: 80 Tools

- Control: Professional 5

- TOOLING

- 300 PSI Through-Spindle Coolant System

- BLUM Laser Tool Probe

- Renishaw OMP400 Part Probe

HORIZONTAL MACHINING CENTERS

Mori-Seiki NHX8000

- MACHINE TRAVELS

- X: 1,400mm (55.1")

- Y: 1,200mm (47.2")

- Z: 1,350mm (53.1")

- SPECIFICATIONS

- Spindle: HSK-100A | RPM: 15,000

- (2) 800 x 800mm Pallets

- Full Contouring 'B' Axis (0.001 degree)

- Load Capacity: 3,000 kg. (6,614 lbs.)

- ATC Capacity: 120 Tools

- Control: Fanuc 31i-MODEL A5

- TOOLING

- 1,000 PSI Through-Spindle Coolant System

- Renishaw RMP600 Part Probe

- Renishaw Tool Setter Touch Probe

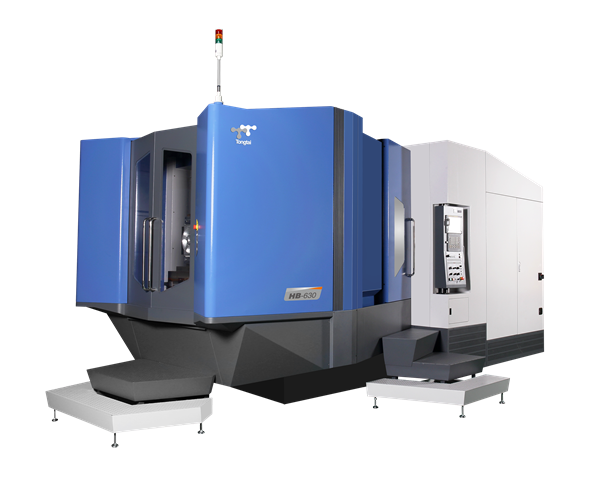

Tongtai Topper HB-630

- MACHINE TRAVELS

- X: 1,050mm (41.0")

- Y: 850mm (34.0")

- Z: 970mm (38.0")

- SPECIFICATIONS

- Spindle: CAT50 | RPM: 10,000

- (2) 630 x 630mm Pallets

- Full Contouring 'B' Axis (0.001 degree)

- Load Capacity: 1,200 kg. (2,640 lbs.)

- ATC Capacity: 120 Tools

- Control: Fanuc 31i-MODEL B

- TOOLING

- 1,000 PSI Through-Spindle Coolant System

- Renishaw RMP600 Part Probe

- Renishaw Tool Setter Touch Probe

Tongtai Topper HB-500

- MACHINE TRAVELS

- X: 800mm (32.0")

- Y: 710mm (28.0")

- Z: 710mm (28.0")

- SPECIFICATIONS

- Spindle: CAT50 | RPM: 10,000

- (2) 500 x 500mm Pallets

- Full Contouring 'B' Axis (0.001 degree)

- Load Capacity: 600 kg. (1,323 lbs.)

- ATC Capacity: 60 Tools

- Control: Fanuc 31i-MODEL B

- TOOLING

- Equipped with Chick Tombstone

- 1,000 PSI Through-Spindle Coolant System

- Renishaw RMP600 Part Probe

- Renishaw Tool Setter Touch Probe

Yasda YBM H40

- MACHINE TRAVELS

- X: 650mm (25.6")

- Y: 560mm (22.0")

- Z: 560mm (22.0")

- SPECIFICATIONS

- Spindle: BT40 BIG-Plus | RPM: 12,000

- (6) 400 x 400mm Pallets

- Full Contouring 'B' Axis (0.001 degree)

- Load Capacity: 400 kg. (881.85 lbs.)

- ATC Capacity: 100 Tools

- Control: Fanuc 16i-MA

- TOOLING

- 300 PSI Through-Spindle Coolant System

- Renishaw OMP400 Part Probe

TURNING

Okuma LB4000 EX II MY X 2000 Lathe

DETAILS COMING SOON

- MACHINE TRAVELS

- SPECIFICATIONS

- TOOLING

WIRE EDM

GF Cut P 800 Pro

- MACHINE TRAVELS

- X: 800mm (31.5")

- Y: 550mm (21.65")

- Z: 510mm (20.07")

- U: 800mm (31.5")

- V: 550mm (21.65")

- SPECIFICATIONS

- Maximum Workpiece Dimensions

- Top Load: 1,450mm (57.08") x 550mm (37.4") x 510mm (20.07")

- Front Load: 1,450mm (57.08") x 950mm (21.65") x 510mm (20.07")

- Load Capacity: 3,000 kg. (6,614 lbs.)

- Maximum Workpiece Dimensions

- TOOLING

- Equipped with System3R Tooling

SURFACE GRINDING

Proth PSGS-4080AHR

- SPECIFICATIONS

- Maximum Travel (cross x longitudinal): 460 x 900mm

- Spindle Center Height from Table: 600mm

- Maximum Height: 422mm

- Grinding Surface of Table: 400 x 800mm

CAD/CAM SOFTWARE

All of our high-speed machining centers are programmed using CAM-TOOL software.

(2) CAM-TOOL MX Software Licenses

TOOLING

We use high-quality LISTA tooling storage cabinets to store all of our high-end cutting tools, toolholders and inspection equipment, which keeps our tooling not only accessible, but our facility well-organized.

Solid Carbide Cutting Tools

We maintain a large inventory of solid carbide cutting tools from industry leading manufacturers such as OSG to ensure we have the best tools to efficiently machine a variety of materials in a timely manner. These cutting tools feature the best coatings and cutter geometry that the industry has to offer.

Solid Carbide Drills

We maintain a large inventory of solid carbide drills from Mitsubishi Materials for high accuracy and efficient drilling of a wide-range of tool steels. These drills feature unique coatings and coolant supply for extended tool life. Our drills range from 3mm to 22mm in diameter.

Toolholders

-

- HSK-63A and -100A

- Is widely viewed as the industry standard for hard milling and high-speed machining (HSM). Utilizing HAIMER shrink-fit tool holding ensures balanced tooling for safe and smooth operation up to 24,000 RPM.

- Is widely viewed as the industry standard for hard milling and high-speed machining (HSM). Utilizing HAIMER shrink-fit tool holding ensures balanced tooling for safe and smooth operation up to 24,000 RPM.

- BT40 BIG-Plus

- As featured on our Yasda CNC Jig Borers, these holders are used for roughing and finishing, combining full taper and flange contact for increased rigidity and reduce runout for balanced performance and smooth operation at high spindle speeds.

- As featured on our Yasda CNC Jig Borers, these holders are used for roughing and finishing, combining full taper and flange contact for increased rigidity and reduce runout for balanced performance and smooth operation at high spindle speeds.

- CAT50

- These rigid toolholders as featured on our horizontal machining centers are perfect for all roughing operations that call for extreme material removal.

- HSK-63A and -100A

Shrink Fit Technology

(2) HAIMER Power Clamp Comfort Inductive Heat Shrink Machines

WORKHOLDING CAPABILITIES

Various Tecnomagnete Magnetic Workholding Chucks

(2) 6" KURT Vises

(1) Yasda YPV-125 Precision Vise

(1) Golden Sun 4th Axis Rotary Table

(1) Chick Tombstone

FCS SYSTEM

The FCS modular clamping system (Breyl) is an patented integrated system for the production industry. Its primary focus is increasing production time by allowing unrestricted access to five (5) surfaces while reducing overall setup times.

Benefits:

- Unrestricted access to five (5) surfaces of the workpiece

- Easy optimization and workpiece positioning due to clamping and pallet options available

- The capability for the piece to be set in the best position achievable for machining efficiency

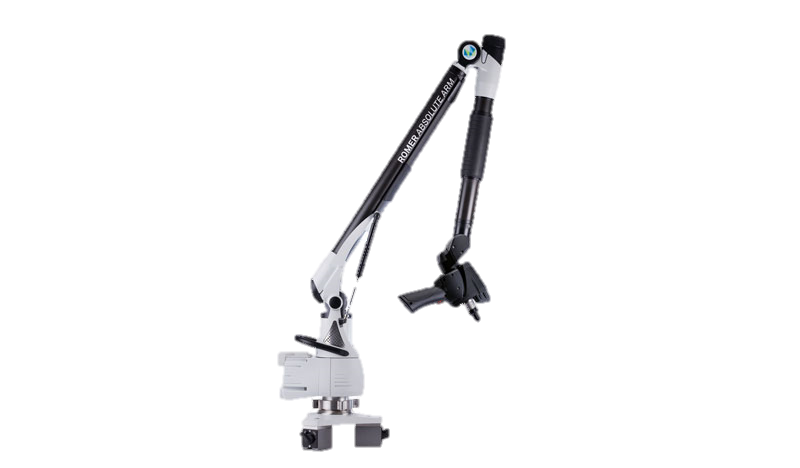

INSPECTION AND QUALITY CONTROL EQUIPMENT

(1) ROMER Absolute 7520 SEI Arm

INSPECTION SOFTWARE

(1) CappsNC Programming Software License (with CappsNC Execution Module)

(1) PolyWorks Inspector Premium + Meshing Software License

ROCKLINIZER

The Rocklinizer, a carbide application system electronically impregnates and deposits wear-resistant material both underneath and on top of metal surfaces utilizing their proven spark deposition process. Unlike welding or metal spraying, no appreciable heat is generated; and the electrode material will not separate or flake off the workpiece.

(2) Rocklinizer Model 850E Carbide Application System

The Rocklinizer Model 850E deposits from 0.0025mm to 0.1778mm (0.0002" to 0.007") in a single application, controllable within 0.0025mm (0.0001") by machine setting.

MITRE UPCUT SAW CAPABILITIES

PMI-20 Upcut Saw

The PMI High-Speed Upcut Aluminum Saw is designed to cut aluminum profiles quickly and accurately.

- CUTTING CAPACITY

- Round: 5.905"

- Maximum Width: 13.188"

- TABLE SIZE

- X: 905mm (35.6")

- Y: 905mm (35.6")

- SPECIFICATIONS

- Blade Size: 20" | RPM: 3,000

- Saw Motor: 7.5 HP

- FEATURES

- Upcut design and fully enclosed saw blade chamber

- Pneumatic clamping system with adjustable clamping pressure to prevent distortion of thin walled aluminum extrusions

- Saw blade feed controlled via air/hydraulic

- Precise micro-drip blade lubrication system

MATERIAL HANDLING CAPABILITIES

(1) Hyster 80 Forklift (8,000 lbs. capacity)

Various Jib Cranes (500 - 2,000 lbs. capacity)

Baxter 360SA Semi-Automatic Horizontal Bandsaw